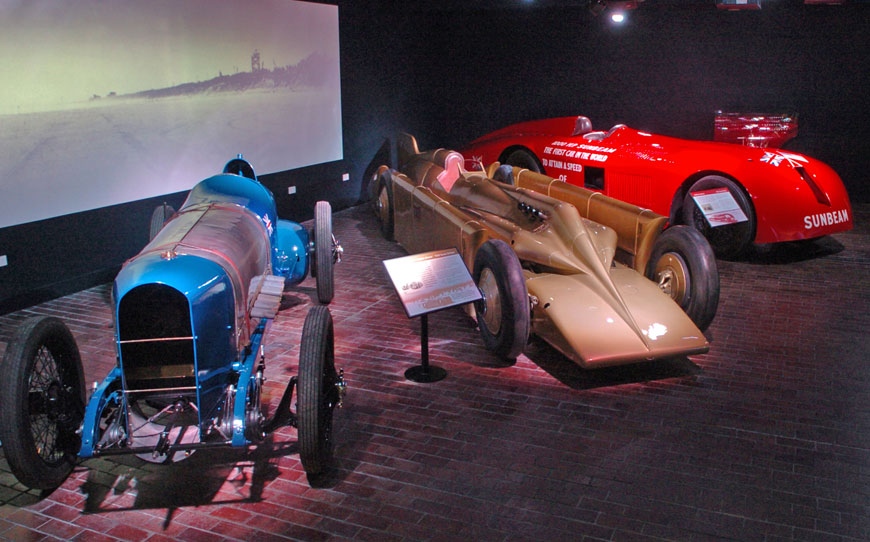

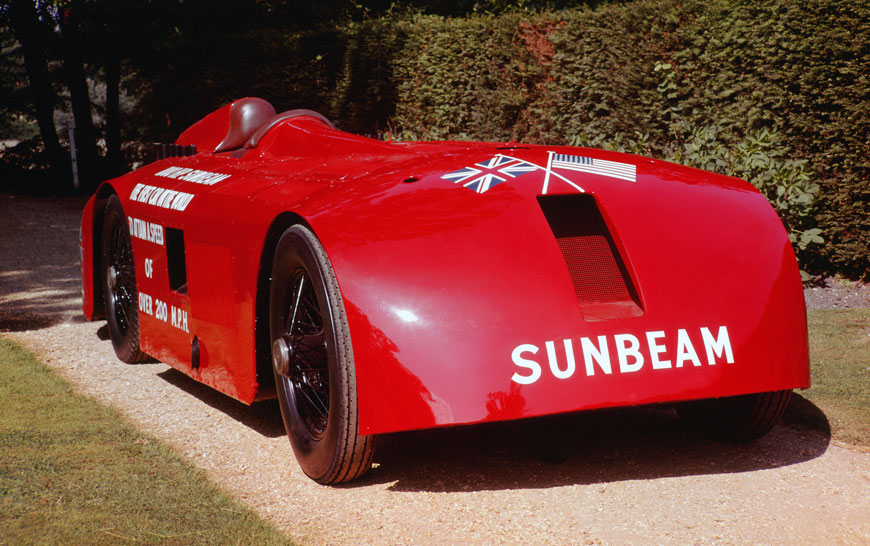

In the 90th anniversary year of Major Henry Segrave’s 1927 World Land Speed Record, more progress has been made with the restoration of the National Motor Museum’s Sunbeam 1000hp. The focus of this year’s project has been to breathe new life into one of the iconic car’s colossal V12 engines.

Over the summer, new work has included making the engine’s two carburettors fit for purpose once again. Missing distributors and non-return valves for the air-start system have now been re-made. New hose clips have been found amongst the treasures at Beaulieu’s International Autojumble and the engine exterior has been repainted.

The challenge now remains to find funding for the project to be completed, so that the engine can run again.

MORE PROGRESS

The Sunbeam is fitted with four hefty carburettors, feeding fuel and air to the two V12 aero engines. After decades of sitting idle, the carburettors that serve the rear engine were seized, coated in grime and in need of careful restoration.

Each has been stripped down, carefully cleaned and inspected for signs of wear, before its components have been deemed fit for further service. Fortunately, these carburettors are similar to those recently rebuilt by the workshop engineers for the museum’s record-breaking 1920 Sunbeam 350hp ‘Blue Bird’, meaning that they were familiar with the design.

Serious thought was required, however, for the engine’s air-start mechanism. Air starting is normally used for very large capacity, low-revving engines when an electric starter motor wouldn’t be powerful enough. It works by forcing pressurised air via a distributor into each cylinder which, in turn, forces down the pistons and turns the engine over fast enough to fire it up.

When the Sunbeam 1000hp arrived at Beaulieu in 1958, both of its engines were fitted with notices which stated that vital parts were missing. These turned out to be from the incomplete air-start system. The distributors, which control the supply of air to each cylinder at exactly the right time, were long gone, as were a number of the non-return valves which should have been fitted to the cylinders.

Tracking down replacements was an impossible task, meaning that new ones have had to be expertly made. An air-start distributor borrowed from a rare Sunbeam Aero engine displayed by the Rolls-Royce Heritage Trust, Derby, was used as the pattern for a specialist. New distributors have been created and precisely machined to fit. The non-return valves for the cylinders have also been re-made, along with the high pressure air lines that supply them.

ATTENTION TO DETAIL

. . . is the key for any rebuild of a historic vehicle, especially one as significant as the Sunbeam. Even small components can be vital to maintaining an as-original appearance, with often overlooked items such as the retaining clips for the cooling hoses being important to getting the original look.

Unsurprisingly, the hose clips on the Sunbeam were well past their best. Re-using these tired items was not an option but modern equivalents had to look right. A box of new, old-stock clips of an almost identical design was found by Beaulieu’s engineers at our International Autojumble in September and provided the ideal solution.

The original black paint finish on the engine exterior needed attention, so was also completely stripped as part of the cleaning and de-greasing process. To protect the now spotlessly clean crankcase, blocks and cam boxes, these were treated to coats of primer, before being sprayed with black top coats. The resulting shiny, hard-wearing finish means that the engine will look as it did in 1927.

THE NEXT STEP

Although great strides have been made, a project such as this cannot be rushed. Further specialist machining work and careful preparation is still required for some of the components before the engine can be reassembled – and further funding is needed before that can happen.

A restoration fundraising appeal is not currently planned for the Sunbeam 1000hp but if you are keen to help with funding support, please get in touch at pr@beaulieu.co.uk. This marathon engine rebuild isn’t over yet but at some point in the future, the Sunbeam 1000hp will roar again.