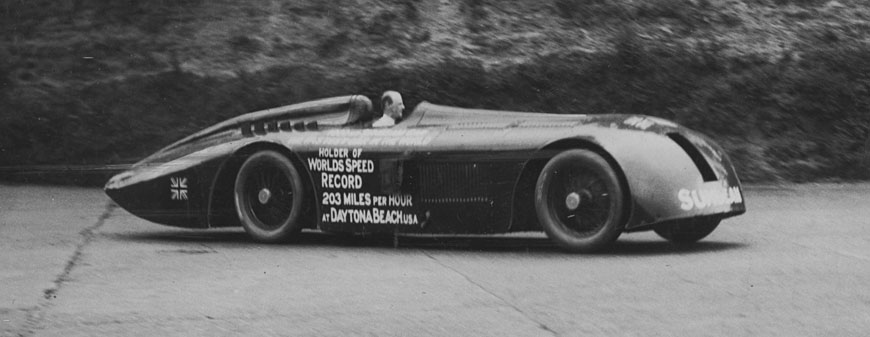

The National Motor Museum has embarked on the restoration of one of the engines of the 1927 Sunbeam 1000hp, the iconic first car ever to exceed the 200mph barrier. As this challenging project gathers momentum, the National Motor Museum’s Chief Engineer and Museum Manager Doug Hill tells the story so far . . .

Warning notice

This simply amazing motor car is powered by two 22.5-litre V12 aero engines.

The car first arrived at Beaulieu in 1958, becoming one of the star attractions in the Montagu Motor Museum, the forerunner to the National Motor Museum. However, both of its engines were fitted with engraved plaques saying: “Engine will not start owing to vital part of mechanism being removed.”

The last documented time the engines were run was for the car to be demonstrated at Brooklands race circuit in 1939.

So not knowing which parts were missing and with the gear selection mechanism not functioning, there was no way to turn the engines. There was also never a desire to disturb the engines which we believed were kept perfectly safe by being correctly inhibited and sealed when the car was decommissioned.

Decision time

The National Motor Museum has a system where we endeavour to ensure all of the engines in our care are turned and kept in the best possible condition. Part of this process is to survey the mechanical well-being of vehicles we know are not capable of running. The Sunbeam 1000hp was one such vehicle.

On careful inspection, we found that the engines were virtually complete and only parts of the air-start mechanism were missing . . . but were saddened to discover that they had not been inhibited at all. As a result, we uncovered a disappointing amount of corrosion within the inlet and exhaust ports and the start of surface corrosion on the crankshaft and con rods. The engines had also been left with high-performance Castrol R oil in them and were virtually glued solid!

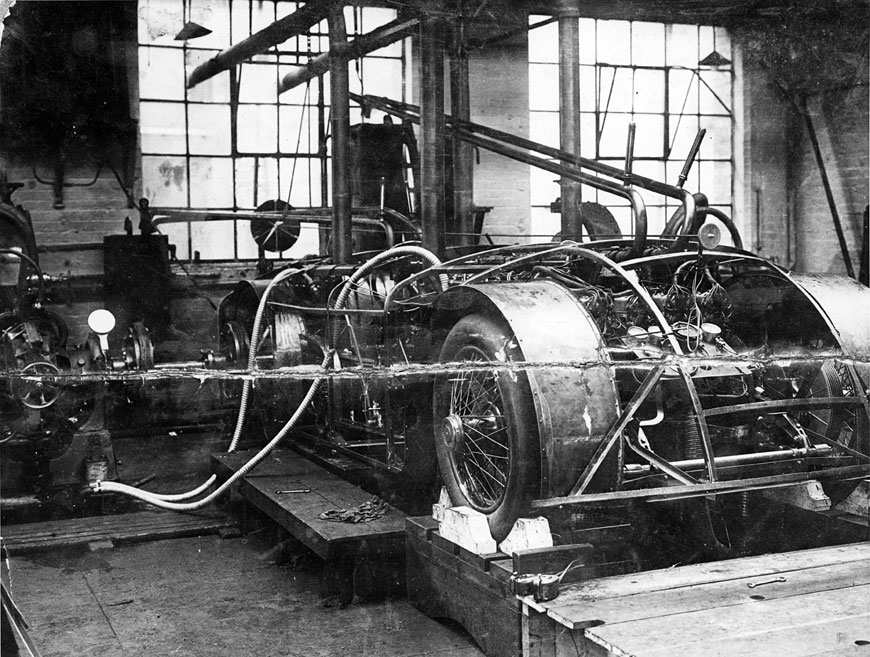

It was decided at this stage that something had to be done to save these unique engines from any further corrosion damage. The only way to achieve this was to remove the engines from the car in order to free them off and to disassemble them and treat the corrosion accordingly.

Work begins

It took 18 months of painstaking work for the museum engineers to free off and disassemble the rear engine. We had struck just in time and it was possible to salvage the engine and halt and even reverse the deterioration.

Following the great work the museum engineers had achieved in restoring the 18.23-litre V12 engine in our 1920 Sunbeam 350hp, techniques and knowledge had been acquired by the team. So we knew it would be relatively straightforward to continue the work on the 1000hp’s rear engine and to return it to running condition.

Work is now well underway and during this 90th anniversary year of the car achieving its Land Speed Record, the engineers are busy rebuilding the car’s rear engine so that it can run again while mounted in a test frame.

Once this momentous goal has been achieved, work can then start on the car’s front engine. During this second rebuild, we will be in a position to make decisions about returning the car to full running order so that we can drive it again in the future.